Darekon’s operations in 2023 have returned to a stable development path after the disturbance that marked the previous year. Darekon Group’s turnover in 2023 was 87.2 million euros and operating profit was 4.2 million euros. The corresponding figures for 2022 were €85.6 million and €1.6 million.

Nowości

Darekon continues its steady development

Delivery times for electronic components have returned to normal and this is believed to have reduced the company’s inventories. The group’s operating profit percentage was 4.8 last year, the equity ratio was 36% and the number of employees was 490 at the end of 2023. An increase in personnel by 40 people took place mainly at the Haapavesi manufacturing facility.

A solid foundation for the future

Darekon Group’s structure has been modified in recent years and the current structure – three electronics manufacturing facilities (in Finland, Poland and Sweden) and two mechanical production sites in Finland – provide a good foundation for the future. A 1,200m 2 expansion of the firm’s Haapavesi site’s production facilities is nearing completion and, at the same time, a 120kWp solar power plant on the roof of the facility will be commissioned.

The integration of Darekon AB and Premec Oy, acquired just over two years ago, into the group’s operations has progressed well. The group’s common enterprise resource planning system was put into use at Premec at the beginning of 2023 and at Darekon AB at the beginning of the current year. Darekon AB is currently moving to new premises in Stockholm, doubling the available space.

The sustainability reporting started last year is being further developed and an ESG manager was hired by the group at the beginning of this year. Last year, a business controller was also recruited and, under his leadership, plant reporting has been developed and a database-based system introduced to support and report on the daily management of the facilities.

Moderate organic growth

Moderate organic growth and stabilisation of profitability to a more typical good level are expected for the financial period that has started.

Darekon’s customer base is now grouped more clearly, into four industry groups: Medtech; Cleantech; aerospace and defence; and advanced industrials.

Investments have been planned for the current year, particularly taking into account environmental aspects and customer needs.

Darekon keeps growing

Despite a challenging business environment, Darekon’s operations in 2022 were marked by strong growth and the integration of acquisitions made in the previous year.

Darekon Group’s turnover in 2022 was EUR 85.6 million and operating profit was EUR 1.6 million. The acquisitions of the previous year are included in the figures of the completed financial year for the whole year. The corresponding figures for 2021 were EUR 52.9 million and EUR 2.9 million.

Adaptation to prevailing conditions

During the last two financial years, Darekon’s inventory has been significantly increased in order to serve customers as strongly as possible despite the difficult availability of electronic components. In addition, the net sales of last year include EUR 10 million worth of electronic components purchased on the spot market and invoiced to customers. The corresponding amount of the previous fiscal year was EUR 2 million.

In the completed financial year, Darekon Group’s profitability was weakened by the challenges of the supply chain in the electronics industry and strong inflation. Increasing the firm’s inventory and lower than normal profitability has increased the need for working capital. That need has been met with external capital.

The results of the fiscal year includes credit losses and the costs incurred from the closure of the Savonlinna manufacturing facility. The combined effect of these non-recurring expenses, which weakened the results, was approximately EUR 1.5 million. EUR 0.5 million were invested in R&D at the group level.

Growth continues and profitability improves

The turnover for the current year has been budgeted at EUR 92 million, and the development of the first quarter is on track. In the current fiscal year, the spot market purchases made on behalf of customers have decreased and the availability of components has improved overall. Thanks to this, the value of inventories is expected to decrease during the year.

Darekon Group’s operations are expected to grow and profitability to improve to the level before corona virus. In the completed fiscal year, the number of personnel was an average of 453 people. Thanks to increased demand at the beginning of the year, staff have been recruited and numbers are approaching 500 people.

Darekon Oy continues expanding with the acquisition of Premec Oy

With the contract signed on December 30. Darekon has acquired all shares of sheet metal contract manufacturer Premec Oy. With the acquisition Darekon keeps strengthening its sheet metal business and expanding their service portfolio. The operations of Premec Oy will continue in Ylivieska as they are, and the previous owners will carry on working for the company.

The acquisition of Premec is in line with Darekon’s strategy to strengthen its operations as a contract manufacturer of electronics and all the related products. This past year Darekon has previously acquired IdeasPaint´s painting operations in Klaukkala and a Swedish contract manufacturer IHAAB Component Systems AB in Stockholm.

Premec Oy is a profitable and solvent service company specializing in the manufacture of demanding mechanical parts and assemblies. Its key competence areas include sheet metal work, design and product development. The company’s financial year which ended in the end of September 2021 saw them record sales of over 15 million euros with 100 staff members. The company works in a modern 7500 m² production facility in Ylivieska.

Premec will become a part of Darekon group, and its operations will be developed with long-term goals in mind. The resources of Darekon and their financial solidity will further improve Premec’s possibilities to grow and improve their position in growing customer markets.

“Premec fits perfectly to Darekon’s service portfolio. The capable personnel and the good, versatile customer base create excellent starting point for development. This acquisition will support our long-term growth strategy incredibly well. We are aiming for 75-million-euro revenue in 2022”, states Darekon’s CEO Kai Orpo.

“Premec will get a fine home from Darekon. We saw with the other owners that joining Darekon will let us have the best conditions to develop to the next level. I firmly believe that our good development will continue, and we will be able to serve our customers better and more broadly”, adds Premec’s managing director Juha Männistö.

Darekon has acquired a Swedish electronics contract manufacturer

Darekon has acquired the entire share capital of Swedish firm IHAAB Component Systems AB in Stockholm, following an agreement signed on the 6th of September. The company’s subsidiaries SMD Production AB and Kelab Systems AB are included in the transaction. The acquisition is part of Darekon’s planned strategy of international expansion.

SMD Production AB and its sister company Kelab Systems AB offer their customers electronics contract manufacturing. They specialize in the manufacture of medical equipment and industrial electronics.

The company’s turnover is about forty million SEK; its more than 20 employees operate in 1,000 square meters of space in Stockholm. It fits perfectly to Darekon. Right customer base and knowledgeable personnel.

The company’s operations will continue as before and the previous owner and CEO Peter Strömgren will continue as CEO for the time being.

The acquired company’s operations and cooperation with Darekon’s other plants will be developed on a long-term basis. The company’s skilled staff also bring more expertise and local knowledge to Darekon’s organisation. Darekon’s greater resources and good financial standing will also give the acquired company even better opportunities to grow and strengthen its position in the Swedish market.

“The Swedish market is interesting for us. Through the acquisition, our knowledge of the Swedish market will improve and we will learn more about the local supplier field, for example. We believe in the industry and want to move forward. This acquisition provides excellent support for our long-term growth strategy.” summarizes Darekon´s CEO Kai Orpo.

“When I was approached by Darekon in 2018 I immediately saw a great opportunity for SMD/ KELAB to be part of something much bigger. With the ambition and strength of Darekon and the platform that SMD/KELAB represents in Sweden I strongly believe that this will develop to be a successful combination in the Swedish market for contract manufacturing.” adds Peter Strömgren.

For more information you can contact:

Kai Orpo/ Oy Darekon Ltd

Tel. +358 40 500 05 62

Kai.orpo@darekon.fi

Peter Strömgren/ SMD Production AB

Tel- +46 70 580 29 00

Peter.stromgren@telia.com

Oy Darekon Ltd is a contract manufacturer of medical devices and industrial electronics. Darekon was established in 1985 and its plants are located in Haapavesi, Klaukkala, Savonlinna in Finland and Gdansk in Poland. Company’s turnover was 53 million euros in 2020 and the amount of employees is more than 300. www.darekon.com

2020 was a good year for Darekon both operationally and financially

The past year was labeled by many successful arrangements such as, streamlining of operations, significant investments in the development of production at different plants, and at the end of the year business acquisition of a paint shop to strengthen our company’s supply chain.

Last spring Darekon increased the amount of time staff spent working from home as much as possible. All business travel was reduced to a minimum to ensure the health of our staff. The operations of all manufacturing facilities have continued uninterrupted throughout the year.

Stable organic growth continues

Net sales in 2020 were EUR 53.7 million, an increase of almost six per cent (2019 EUR 51.1 million). Operating profit increased slightly from the previous year and was EUR 3.5 million, or 6.5 per cent. The number of employees at the end of the year was 316, which is one more than the year before. The Darekon Group’s equity ratio was 54.9 per cent.

Last year’s most significant investment was a new and state-of-the-art SMT placement line acquired for the Haapavesi plant in the spring, which almost doubled Haapavesi’s SMT capacity. The investment also included a new solder paste printing machine, a 3D AOI inspection system and a selective soldering machine.

The investment was driven by a strong increase in demand for medical devices in the spring, and the investment was completed on an exceptionally fast schedule.

A new varnishing line was acquired for the Savonlinna plant, which more than doubled the circuit board varnishing capacity and brought new flexibility to the plant’s operations, where many of the manufactured products are meant for particularly demanding conditions.

After years of planning, the investment that most significantly affected the operations of the entire Darekon Group was the introduction of a new ERP, or enterprise resource planning system, at the beginning of last October. The carefully prepared commissioning went ahead without major problems. The new system is a major step forwards, streamlining and helping to develop the company’s operations at all levels.

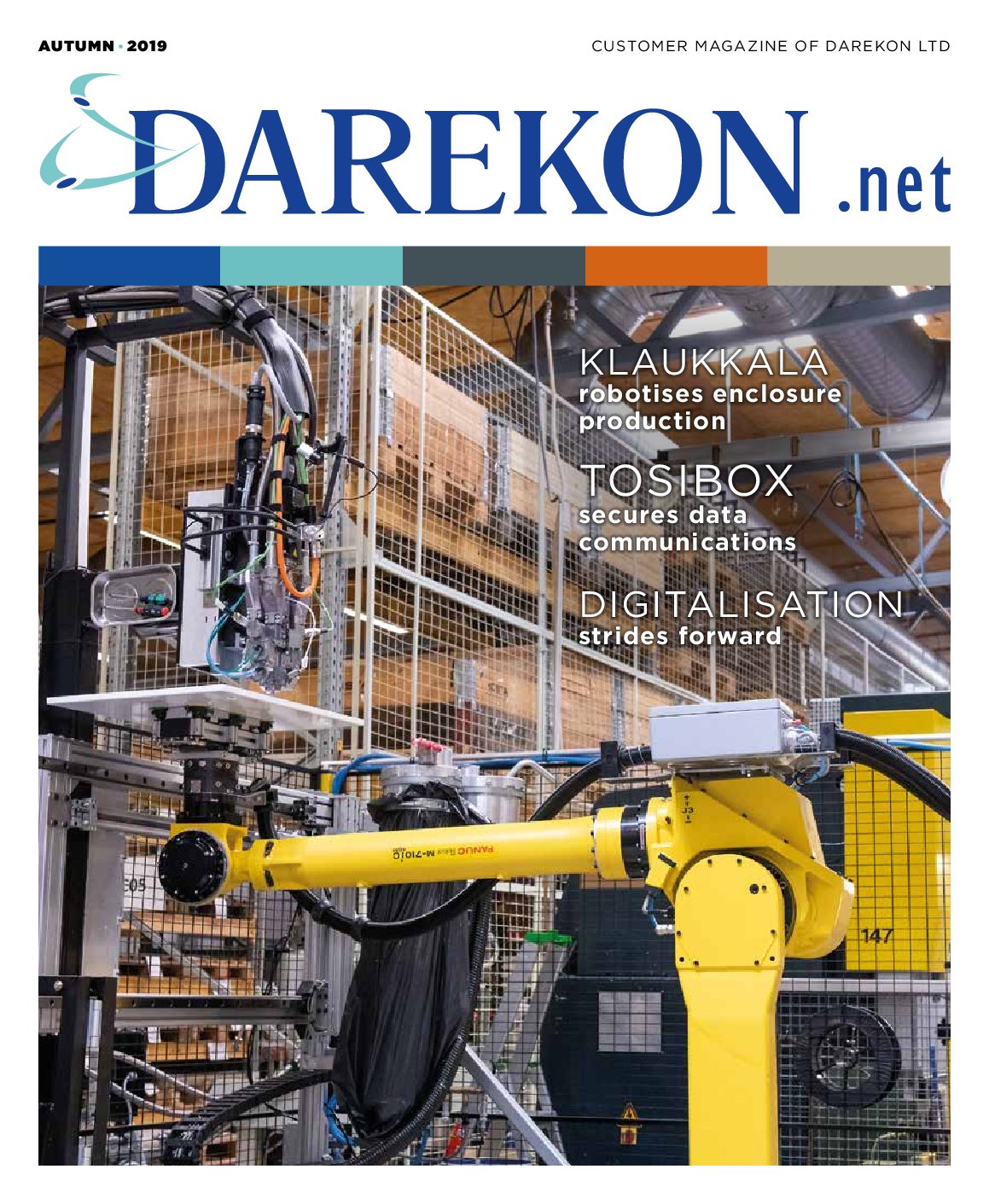

The paint shop expands Klaukkala’s operations

In recent years, the Klaukkala manufacturing facility has put more focus into automated manufacturing of enclosures and equipment cabinets, by investing in, for example, the manufacturing of seals, welding and grinding using robots. Enclosures and cabinets are central to Darekon’s strategy to provide customers with a complete turnkey delivery from PCB manufacturing to final assembly and logistics.

At the end of December, Darekon entered into an agreement to acquire Ideapaint Oy’s Klaukkala paint shop business. The business includes equipment, the transfer of personnel to Darekon’s service as former employees, and 600 square metres of paint shop space on the same property where Darekon already operates. Darekon has previously been a major customer of the unit. The new surface treatment unit complements and enhances Darekon’s competitiveness in enclosure and cabinet manufacturing.

The surface treatment unit can provide powder coating, liquid painting as well as pre-treatment of components to be painted by abrasive blasting. The completed transaction creates new opportunities for the development and expansion of Klaukkala’s paint shop operations together with Darekon’s current and future customers.